-40%

Space Shuttle SRB Main Parachute Frangible Release Nut, with Bolt X-38

$ 155.76

- Description

- Size Guide

Description

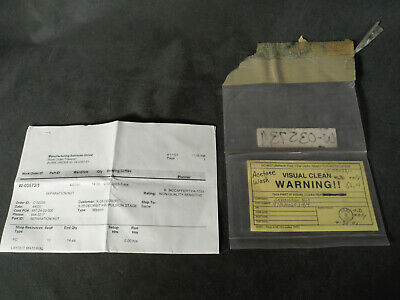

Being offered is this RARE Space Shuttle SRB Main Frangible Parachute Release Nut & Bolt Modified for theX-38 Prototype Crew Return Vehicle Program. Paperwork (Copies will be provided, but Original Paperwork is Not Included), shows it was for the X-38 Deorbit Propulsion Stage. The Release Nut and Bolt come in their original packaging and have never been used.These are ITAR Restricted Items and can not be shipped outside of the USA. Winning bidder will need to sign U. S. EXPORT CONTROLLED CERTIFICATION.

Originally designed as part of the recovery system for the Space Shuttle Solid Rocket Booster, The main chutes are released from the

SRB

at impact using the parachute release nut ordnance system.

Space Shuttle Solid Rocket Booster - Function - Descent and Recovery

Descent and Recovery

The SRBs are jettisoned from the shuttle system at 2 minutes and an altitude of about 146,000 feet (44.5 km). After continuing to rise to about 220,000 feet (67.1 km), the SRBs begin to fall back to earth and once back in the atmosphere are slowed by a parachute system to prevent damage on ocean impact. A command is sent from the orbiter to the SRB just before separation to apply battery power to the recovery logic network. A second, simultaneous command arms the three nose cap thrusters (for deploying the pilot and drogue parachutes), the frustum ring detonator (for main parachute deployment), and the main parachute disconnect ordnance.

The recovery sequence begins with the operation of the high-altitude baroswitch, which triggers the pyrotechnic nose cap thrusters. This ejects the

nose cap

, which deploys the pilot

parachute

. Nose cap separation occurs at a nominal altitude of 15,704 ft (4,787 m), about 218 seconds after SRB separation. The 11.5 ft (3.5 m) diameter conical ribbon pilot parachute provides the force to pull lanyards attached to cut knives, which cut the loop securing the drogue retention straps. This allows the pilot chute to pull the drogue pack from the

SRB

, causing the drogue suspension lines to deploy from their stored position. At full extension of the twelve 105 ft (32 m) suspension lines, the drogue deployment bag is stripped away from the canopy, and the 54 ft (16 m) diameter conical ribbon drogue parachute inflates to its initial reefed condition. The drogue disreefs twice after specified time delays (using redundant 7 and 12-second reefing line cutters), and it reorients/stabilizes the SRB for main chute deployment. The drogue parachute has a design load of approximately 315,000 lb (143,000 kg) and weighs approximately 1,200 lb (540 kg).

After the drogue chute has stabilized the SRB in a tail-first attitude, the frustum is separated from the forward skirt by a pyrotechnic charge triggered by the low-altitude baroswitch at a nominal altitude of 5,500 ft (1,700 m) about 243 seconds after SRB separation. The frustum is then pulled away from the SRB by the drogue

chute

. The main chute suspension lines are pulled out from deployment bags that remain in the frustum. At full extension of the lines, which are 203 ft (62 m) long, the three main chutes are pulled from their deployment bags and inflate to their first reefed condition. The frustum and drogue parachute continue on a separate trajectory to splashdown. After specified time delays (using redundant 10 and 17-second reefing line cutters), the main chute reefing lines are cut and the chutes inflate to their second reefed and full open configurations. The main chute cluster decelerates the SRB to terminal conditions. Each of the 136 ft (41 m) diameter, 20-degree conical ribbon parachutes have a design load of approximately 195,000 lb (88,000 kg) and each weighs approximately 2,180 lb (990 kg). These chutes are the largest that have ever been used — both in deployed size and load weight. The RSRM nozzle extension is severed by a pyrotechnic charge about 20 seconds after frustum separation.

Water impact occurs about 279 seconds after SRB separation at a nominal velocity of 76 feet per second (23 m/s). The water impact range is approximately 130 nmi (240 km) off the eastern coast of Florida. Because the parachutes provide for a nozzle-first impact, air is trapped in the empty (burned out) motor casing, causing the booster to float with the forward end approximately 30 feet (9.1 m) out of the water.

Formerly, the main chutes were released from the SRB at impact using a parachute release nut ordnance system (residual loads in the main chutes would deploy the parachute attach fittings with floats tethered to each fitting).

The current design keeps the main chutes attached during water impact (initial impact and slapdown). Salt Water Activated Release (SWAR) devices are now incorporated into the main chute riser lines to simplify recovery efforts and reduce damage to the SRB. The drogue deployment bag/pilot parachutes, drogue parachutes and frustums, each

main chute

, and the SRBs are buoyant and are recovered.

X-38 Prototype Crew Return Vehicle

The X-38 project was a series of five prototype research vehicles developing technology to build and operate a space station crew return vehicle (CRV). The wingless CRV, when operational, would be the first reusable human spacecraft to be built in more than two decades

The design of the X-38 incorporates the wingless lifting body concept pioneered at Dryden. Six unique lifting body configurations were tested at Dryden between 1963 and 1975. Data from the aerodynamic studies contributed to the design and operational profile of the space shuttles and is reemerging to help develop the CRV.

The X-38 design closely resembles the X-24A lifting body flown at Dryden from April 1969 to 1971. Wingless lifting bodies generate aerodynamic lift - essential to flight in the atmosphere - from the shape of their bodies.

The 28 research missions flown by the X-24A helped demonstrate that hypersonic vehicles like the space shuttle returning from orbital flight could be landed on conventional runways without power. The X-24A was modified in 1970 and designated the X-24B in 1971, the last lifting body configuration was tested in the 12-year research program at Dryden.